- PREPARATION

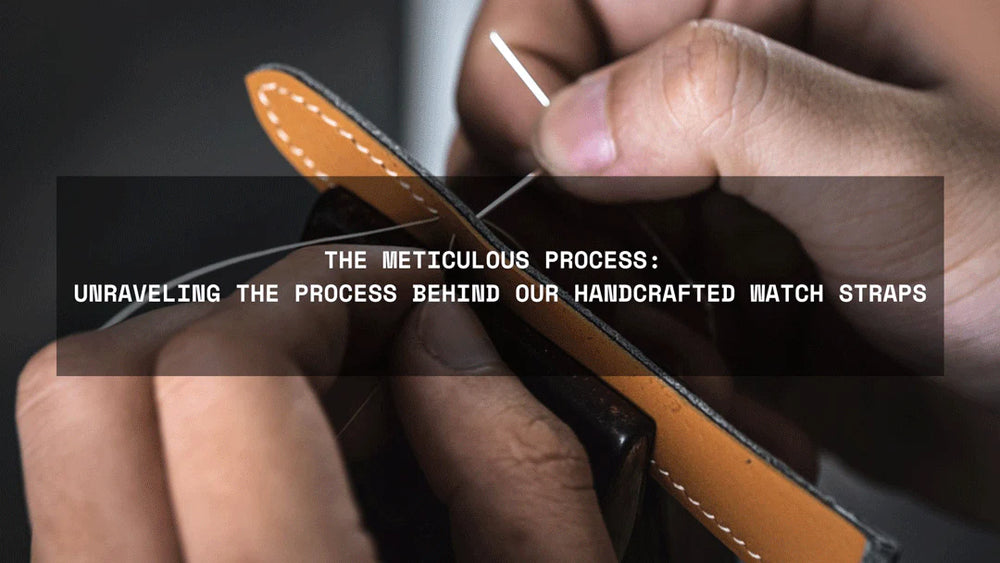

- STITCHING

- COMING TO LIFE

- FINISHING TOUCHES

At House of Noori, we take great pride in the meticulous process involved in crafting our exquisite watch straps. It all begins with a meticulous selection process where we source for the finest premium leather hides, importing them exclusively from top-tier tanneries renowned for exceptional leather. Our unwavering commitment to quality is evident as we carefully consider every detail, from the texture to the optimal thickness, ensuring that each strap possesses a remarkable character that perfectly complements the desired style and guarantees long-lasting durability

Before any craft, our team of skilled craftsmen at House of Noori would perform a comprehensive inspection of each leather hide. Leveraging their expertise and trained eyes, they scrutinize every inch to identify even the slightest flaw, blemish, or imperfection. Only the sections of the hide that surpass our standards are chosen, ensuring that our watch straps are crafted exclusively from the most impeccable leather selections available

Our craftsmen would first cut the leather into strapblanks. The blanks are marked and carefully cut with precision.

To account for adjustments, the blanks are cut larger than the desired size

Next, the blanks would be skived. Skiving is a process where the ends of the leather strap blanks are gradually thinned with a sharp skiving knife. This ensures that the strap thickness remains consistent in folded areas

The craftsman proceeds to cut the leather strap blanks into the desired shape and size. Precision and accuracy are paramount at this stage to ensure that the straps are uniform and perfectly cut

The craftsman meticulously aligns the cut leather pieces and bonds them together using adhesive. This step requires careful attention to detail to ensure that the edges match seamlessly and the strap forms a cohesive unit

A light guiding crease would be done along the edge of the strap to serve as a guide for the stitching process and ensure uniformity and accuracy

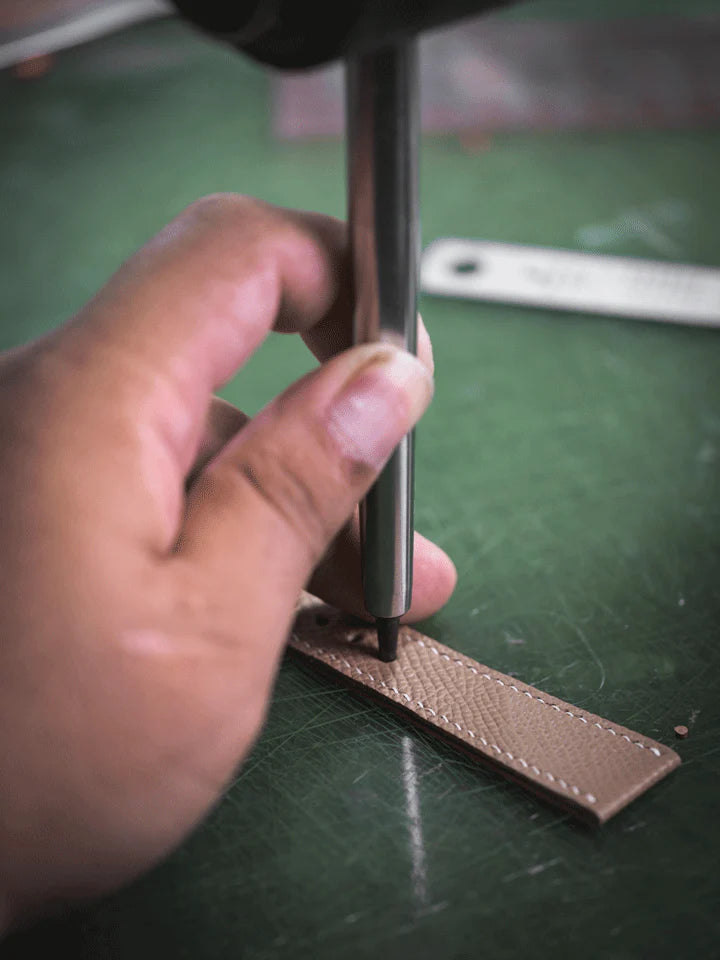

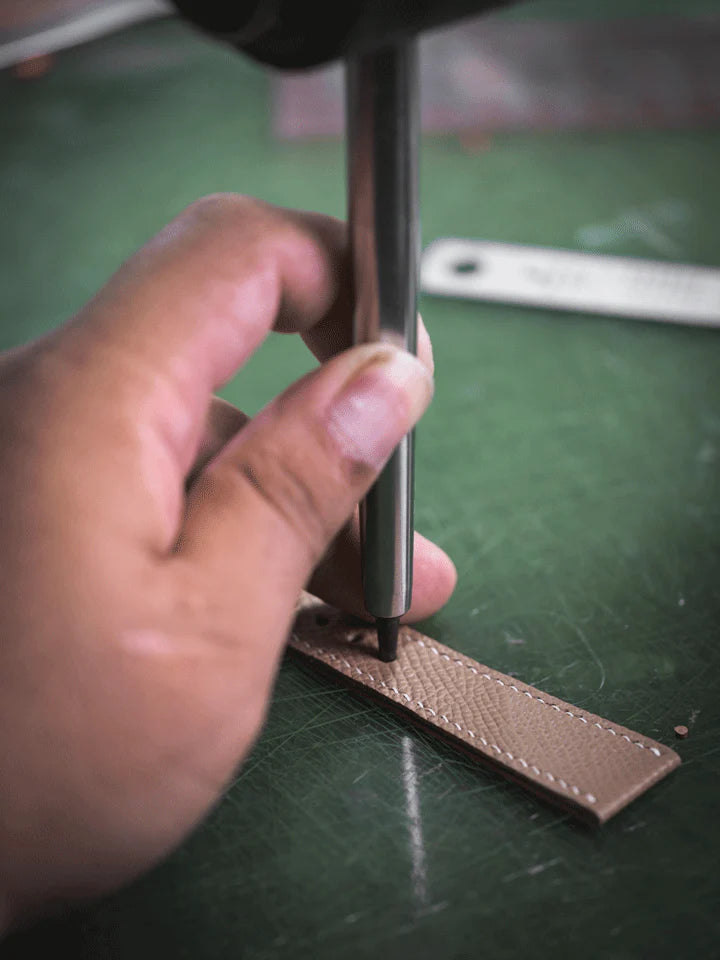

Once the crease lines are made, the next step involves marking holes with the French Irons along the crease line of the strap

The craftsman would then carefully align the French Iron with the markings made earlier and punch the evenly spaced holes by hammering the French Irons through the leather. These holes serves as entry and exit points for the stitching thread

Our crafters undertake a meticulous procedure involving the application, drying, and sanding of multiple layers of edge paint to achieve an exceptional outcome that showcases remarkable weatherproofing capabilities and a flawlessly smooth consistent finish

Once the strap has been checked and ensured of the quality, the "House of Noori" logo would be prominently stamped onto the underside of each strap. Every strap would also have the lug width and length stamped on the underside for easy identification of the various strap sizes. We believe that these small, thoughtful additions would certainly help to enhance the user experience especially when there is a collection of straps of various sizes

Stitching the fixed and free loops

The last step involves attaching our House of Noori buckle, made of 316L stainless steel